Five major preventive measures for transformer bushing damage

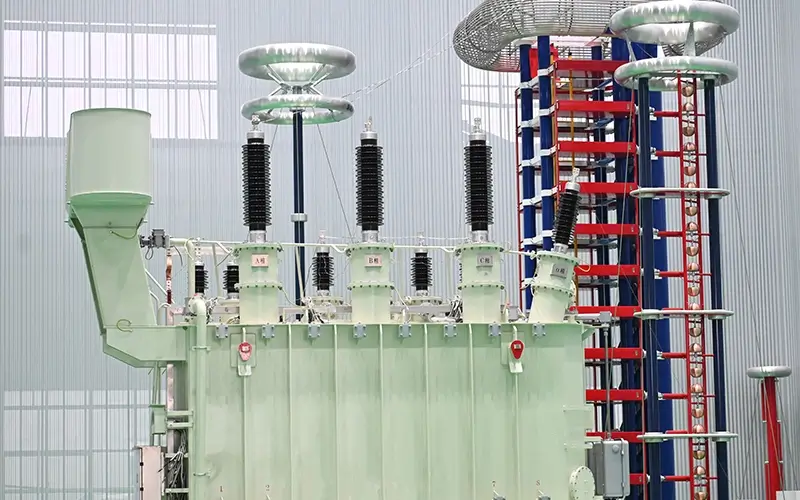

Transformer bushing is a critical component in the safe operation of Power Transformers. Ensuring its durability and performance is crucial to avoid costly failures. Below are five preventive measures to reduce transformer bushing damage:

(1) Transformer bushing manufacturers should improve the level of process quality inspection management to prevent loose insulation paper wrapping, serious wrinkles, and discharge along the wrinkles; prevent capacitor screen size errors, which will cause electric field concentration at the end of the capacitor screen, form dendritic discharge, damage insulation, and cause breakdown explosion.

(2) According to the provisions of the preventive test regulations for power equipment, conduct tests carefully, pay special attention to the changes in dielectric loss angle, capacitance, and chromatographic analysis results. Do not only consider the absolute value of the test results, but also study the relative changes of the results of previous tests, so as to find problems in time and deal with them in time to avoid damage.

(3) Oil leakage defects should be dealt with in time, and the contact heating of the transformer bushing lead terminals should be detected in time.

(4) The vacuum drying treatment of transformer bushings must be thorough during manufacturing, otherwise residual bubbles will remain in the insulation. Under the action of the electric field, these bubbles will withstand a higher electric field strength than solid insulation and produce partial discharge. The discharge will continue to spread and develop under long-term occupational voltage, damaging the insulation. If there is residual moisture, the heat generated in the insulation will exceed the heat distributed to the surrounding area, and the insulation temperature will continue to rise, resulting in thermal instability, which will lead to thermal breakdown.

Check out our ZF28A-126/145 Gas insulated metal enclosed switchgear – Our ZF28A-126/145 Gas insulated metal enclosed switchgear undergo rigorous vacuum drying for superior insulation integrity.

(5) Old and unreliable transformers and transformers that fail the test should be handled as soon as possible. If they need to be disassembled for repair, the transformer bushing should be vacuum-filled after assembly. The vacuum degree and vacuum time should meet the requirements of the manufacturer. After repair, dielectric loss and partial discharge tests under high voltage should be carried out.

Explore YaWei transformer services – We specialize in transformer manufacturing to enhance the reliability and extend the lifespan of your aging equipment.