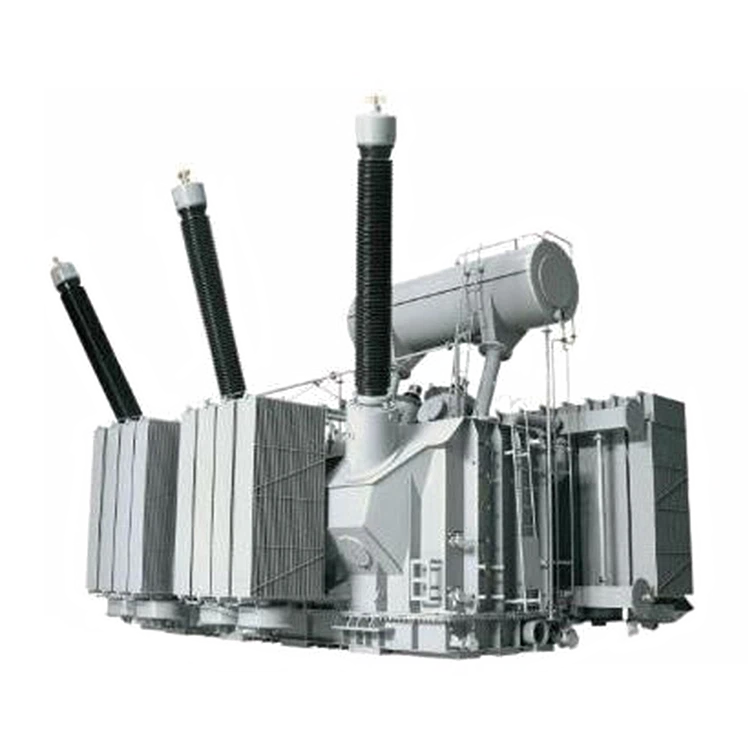

110-220kV oil-immersed power transformer

110-220kV oil-immersed power transformer

The 110-220 KV products produced by the company have formed a standardized structure. The product type has developed from the original 9-type products to the current 10-type, 11-type, 13-type products, and also introduced new products with self-cooling, air-cooled maintenance-free, and no hanging core structure. The product has the following performance characteristics: on-site free core, high efficiency and energy saving, high impedance, low loss, low noise, low temperature rise, low office discharge, that is, one free, two high and four low. This series of products fully meet the market demand for high power supply quality, low loss noise and long maintenance.

1, high temperature resistance is safer

When the ambient temperature is 40℃, it can run continuously for a long time with 100% load

At the same temperature, the continuous load ratio is 20% higher on average than that of the oil-immersed transformer

2, low loss and energy saving

20% energy saving than ordinary oil-immersed transformer.

3, maintenance-free more environmentally friendly

The same life of the seal and the transformer is 20% energy-saving than that of the ordinary oil-immersed transformer.

Process features:

insulation

High temperature resistant hybrid insulation system.

coil

In order to improve the longitudinal capacitance distribution under impulse voltage, the small and medium capacity of the high voltage coil is the entangled one to one continuous type, and the large one is the inner plate one to one continuous type. Coils are guided oil circulation structure, reduce winding temperature rise, product design life of 30 years.

Automatic lamination

The robot is fully automatic lamination, and adopts the full tilt 45 degree 7 step joint structure.

Iron core

The cold-rolled silicon steel sheet with high magnetic permeability and volt-mass orientation will be adopted, non-porous binding, frame structure, D-shaped iron yoke structure for coil lifting large-area platform, and stepped joints. Automatic cutting and laminating robot imported from Switzerland ensures that the core burr is less than 20µm. The multi-stage joint of the iron core reduces the no-load loss, the no-load current and the noise level.

Fuel tank

There are two types of minute mask and bucket structure. All seals are sealed at the end limit; The metal parts inside and outside the box are rounded to remove hair, and the weld seam and seal are tested for three times (fluorescence, positive pressure, negative pressure leakage test); The paint is made according to the rust prevention requirements of household appliances.

Performance characteristics:

Low loss

No-load loss provisions than the current national standard GB64511-2008 should be reduced by 15%-20%, load loss than the current national standard GB64551-2008 by 5%;

Low noise

The self-cooling noise level will reach below 60dB, which is generally nearly 20dB lower than the national standard. Users have special requirements, can also be specially designed and manufactured low noise level;

Low office discharge

The company is 110kV production task, especially the introduction of modern enterprise management mode, 110kV product process will be dust-free operation, the internal metal parts, insulation parts are all rounded, and the office volume is controlled below 100pc.

Strong short-circuit resistance

110kV transformer passed the national certification. Ensure that none of the products are damaged due to sudden short circuit, with strong Reliability:

Beautiful appearance

Full abrasive rust removal, powder electric spraying paint can achieve the effect of home appliance painting, wide chip radiator, never leg color.

non-leakage

All seals are made of acrylic material, and adopt one molding technology, no interface, and solemnly promise not to leak.

Conditions of use:

It is suitable for the distribution network with high load rate at high temperature and the place with impact load and continuous overload requirements. Such as: iron and steel, metallurgical industry, railway traffic, power plants, hydropower stations and so on.

Frequently Asked Questions

Necessitatibus eius consequatur ex aliquid fuga eum quidem sint consectetur velit

Post Comment

Your email address will not be published. Required fields are marked *

You May Also Like

You might be interested in the following content