What is the difference between dry-type transformer and oil-type transformer? How to choose?

01 What is the difference between dry type transformer and wet-type (oil-type) transformer?

In the huge network of the power system, transformers, as key equipment for voltage conversion, have various types and different functions. Among them, dry-type transformers and wet-type (oil-type) transformers are the two most common types. They have significant differences in appearance, structure, performance and application scenarios.

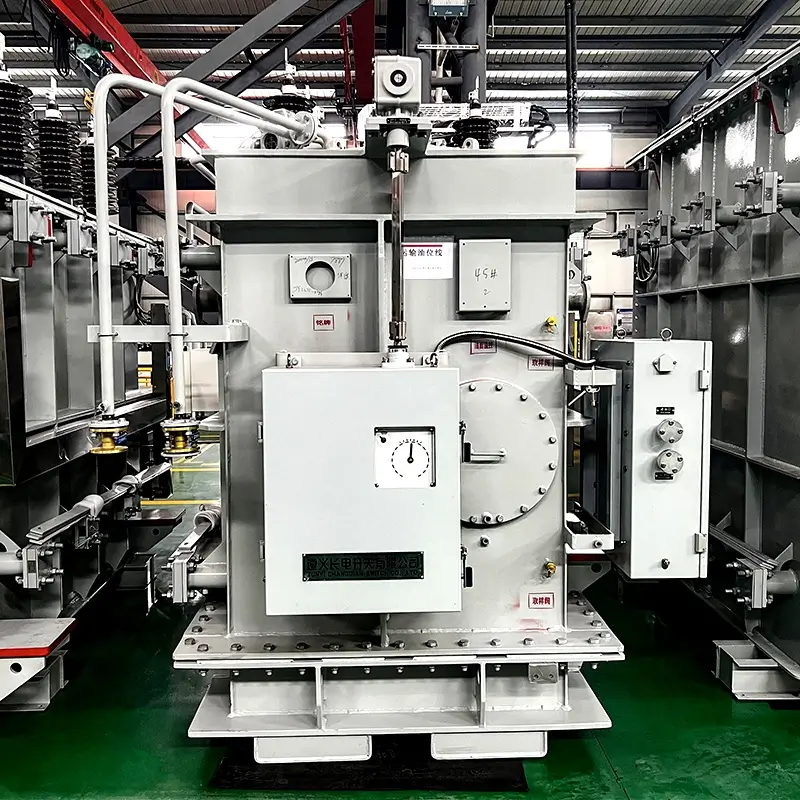

First of all, in appearance, dry-type transformers are obviously different from wet-type transformers. The dry-type transformer is exposed, and its internal iron core and coils can be directly seen. This is because dry-type transformers mostly use natural air cooling or fan cooling and require a good heat dissipation environment. Wet-type (oil-type) transformers are encapsulated in a solid casing, and only their external structure can be seen. This is because the wet transformer is filled with insulating oil, and heat is dissipated through the circulation of oil, so it must be kept sealed. The two also differ in lead form. Dry-type transformers usually use silicone rubber sleeves. This material has good fire-proof and explosion-proof properties and can ensure the safety of the transformer during operation. Wet-type transformers mainly use porcelain bushings, because the presence of internal insulating oil requires higher strength insulating materials for protection.

In terms of capacity and voltage, dry-type transformers are mostly used in power distribution systems. Most of their capacities are below 1600KVA, and their voltage levels are mostly below 10KV, although some products can reach 35KV. In contrast, wet transformers have a wider range of applications, from small transformers to large substations, and can even be seen in my country's ultra-high voltage 1000KV test lines. Insulation and heat dissipation methods are also important differences between the two. Dry-type transformers use resin as the insulating material and dissipate heat through natural air cooling or fan cooling. Wet-type transformers use insulating oil for insulation, and heat is transferred to an external radiator for heat dissipation through the circulation of oil. This difference makes the two different in terms of applicable environment and safety. In addition, in terms of load bearing capacity, dry-type transformers should operate at rated capacity to ensure their stability and safety. Wet-type transformers have good overload capabilities and can withstand loads exceeding the rated capacity to a certain extent. From a cost perspective, dry-type transformers of the same capacity tend to be more expensive than wet-type transformers. This is mainly because dry-type transformers have higher requirements and cost investment in manufacturing processes, insulation materials, and heat dissipation systems.

02 How to choose to install dry-type transformer or oil-immersed transformer? When selecting a Power Transformer, GB/T17468--2008 "Guidelines for the Selection of Power Transformers" and GB4208-2008 "Enclosure Protection Level (IP Code)" should be used as reference standards to ensure that the selected equipment meets the requirements of the specific occasion. environmental needs.

In power systems, the selection of transformers is crucial. It is not only related to the efficiency of power transmission, but also directly affects the safety and stability of the system. When choosing a transformer, a question we often face is: Should we choose a dry-type transformer or an oil-immersed transformer? There is no absolute answer to this question because it depends on a variety of factors, including installation environment, cost budget, performance needs, etc.

First, we need to understand the basic characteristics and applicable scenarios of the two transformers. Dry-type transformers are widely used in large and high-rise buildings due to their fire-proof and explosion-proof characteristics. This is because these places have extremely high requirements for fire safety, and dry-type transformers do not require the use of flammable insulating oil, which greatly reduces the risk of fire. However, although oil-immersed transformers have the risk of oil leakage and oil injection, they have high technological maturity, natural cooling methods, stable quality, excellent short-circuit resistance, and strong overload capabilities in high-humidity and high-temperature environments. and longer life, making it more advantageous in outdoor installations. When choosing, we need to judge based on the specific installation environment. If the installation environment has strict fire safety requirements or the space is limited to accommodate a large amount of cooling equipment, then a dry-type transformer may be a better choice. In addition, if the budget allows and there are high requirements for the performance of the transformer, dry-type transformers are also a good choice. However, if the installation environment is relatively loose and cost is a consideration, an oil-immersed transformer may be more suitable. Its low price and excellent performance make it the first choice in many situations. In addition, oil-immersed transformers also perform better in high-humidity and high-temperature environments, which is particularly important for some special environments. To sum up, the choice of installing a dry-type transformer or an oil-immersed transformer needs to be comprehensively considered based on the specific installation environment, cost budget and performance requirements. Before making a decision, it is recommended to consult a professional power engineer or technician to ensure that the selected transformer can meet actual needs and ensure the safe and stable operation of the power system.