Winter power equipment maintenance and operation protection precautions

With the coming of winter, the changes in temperature and humidity and some other factors brought about by the alternations of seasons will inevitably affect transformers and other electrical equipment. Therefore, in order to ensure the normal and safe operation of electrical equipment in winter, the following aspects need to be paid attention to:

01 Pay attention to the impact of load power consumption changes

1, timely adjust the load of the power line, reasonable selection of matching capacity transformers, to avoid load changes to make some lines appear full load or overload use, seriously affecting the service life of distribution equipment and power safety hazards.

2, to avoid the occurrence of excessive electrical voltage, part of the electrical load may be reduced in winter (such as air conditioning refrigeration), resulting in high line voltage, affecting the service life of electrical equipment. The power consumption unit shall adjust the voltage in time according to the power load demand. When adjusting the tap-changer, ensure that the tap-changer is adjusted in place and the contact is good. If the tap-changer is not in place, it will cause poor contact and heat, and then burn the transformer.

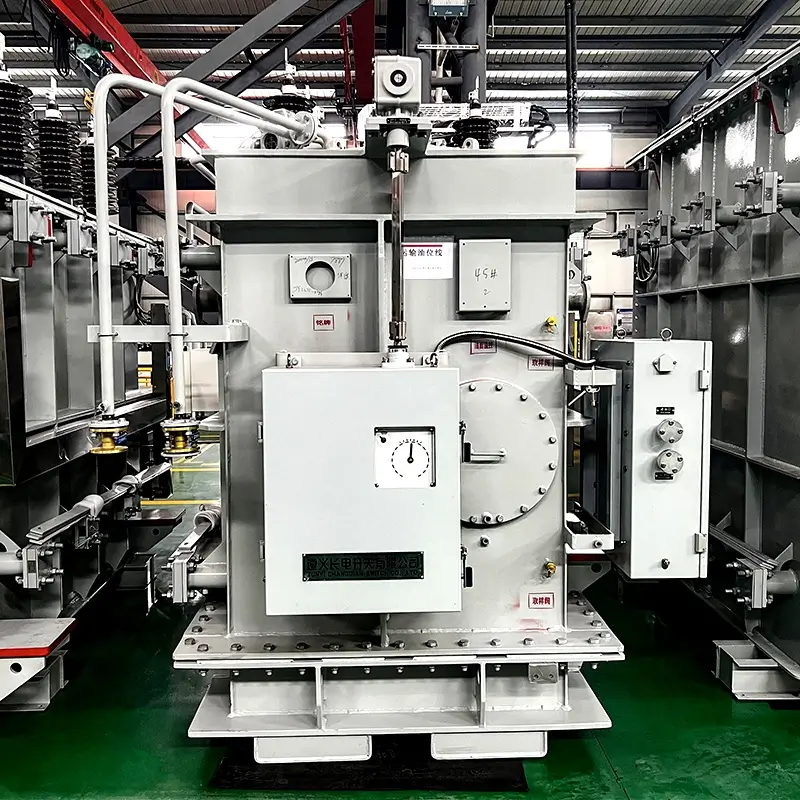

3, load and temperature changes, so that the oil filling equipment sealant pad thermal expansion and contraction, may occur leakage of oil, should be arranged according to the situation maintenance treatment, timely tightening or replacement of seals.

4, strengthen the oil level check of the oil filling equipment, find the problem in time, and do a good job of oil filling treatment, to ensure the safe operation of the transformer and avoid accidents.

02 Focus on the impact of environmental weather changes

1, when the temperature drops sharply in winter, it may cause the oil level of the oil-filled equipment to be lower than the operating requirements, resulting in transformer gas protection misoperation or equipment failure, resulting in accidents.

2, in the case of strong winds in winter, the cable may be shaken and loosened by strong winds. Please check the line regularly (such as the leads on both sides of the transformer inlet and outlet lines) to avoid poor contact, heat or small safety distance caused by loose wire connections, resulting in equipment collapse accidents.

3, outdoor distribution equipment is easy to accumulate water vapor and condensation when the temperature is reduced, resulting in a reduction in the insulation level of electrical components, causing the collapse of the equipment. Therefore, it is necessary to strengthen the management of on-site operations, especially the inspection of on-site temporary electricity consumption.

4, check the environment around the electrical equipment, and find that there is water leakage, gas leakage and metal dust processing areas should be timely waterproof, dustproof, anti-gas treatment to prevent affecting the normal operation of electrical equipment.

03 Strengthen the daily inspection and special inspection of the equipment and its lines

1, transformers, capacitors, switches and other oil-filled equipment, when the temperature changes dramatically, the volume of oil will also change greatly. When the temperature drops sharply, the oil level of the oil-filled equipment may be lower than the operating requirements, resulting in misoperation of the transformer gas protection or equipment failure, resulting in accidents. Similarly, the change of temperature makes the sealant pad of the oil filling equipment expand and shrink, which may cause leakage of oil, and maintenance treatment should be arranged according to the situation. It is necessary to regularly check whether there is oil leakage at the transformer's section switch, pressure valve and high and low pressure bushing, and to tighten and fill oil in time. Strengthen the oil level check of the oil-filled equipment, find the problem in time, and deal with it early, ensure the safe operation of the transformer, and avoid the development of accidents.

2, outdoor power distribution equipment, easy to accumulate water vapor and condensation when the temperature is lowered, resulting in a reduction in the insulation level of electrical components, causing the collapse of equipment, strengthen the management of on-site direct operations, especially the on-site temporary electricity inspection is necessary. Some construction units temporary electric box sealing is not good, in order to wind and snow, with plastic wrap. In the severe winter season, the temperature difference between the inside and outside of the temporary electric box is large, which is easy to form condensation, and it is easy to occur short circuit and collapse accident. Therefore, the temporary power management system must be strictly implemented, and the construction power unit is required to use qualified power boxes.

3, daily inspection of the line system, if found aging lines should be replaced in time, especially the outdoor exposed lines need to pay special attention to avoid leakage caused by aging lines. Please pay more attention to the above precautions, if you have any consultation or needs, you can always call the new energy Zhongwei Power 24h electricity safety service hotline: 400-0591-189, we will be happy to provide you with a one-stop full range of electricity safety service support.

4, in winter, the production device discharged more steam, it may be string into the nearby switch control box, reducing the insulation performance of electrical components. Check whether the switch control box door is tightly closed, whether the fastening bolts are complete and tightened, and negotiate with the production preparation department to solve the exhaust steam mode if necessary.

04 Keep equipment clean to prevent fogging

In autumn and winter, the weather changes greatly, the temperature difference between day and night is intensified, and the water vapor is easy to condense to form fog, frost and snow. If the surface of the insulator is dirty, the leakage current is greatly increased, resulting in a decline in the insulation performance of the insulator, and in serious cases, causing flashover discharge and even power failure.

In winter, the electrical workshop should arrange personnel to clean the outdoor equipment, if necessary, you can also ask the power company to brush the insulators of all the outdoor switches with antifouling flash RTV paint (on the surface of the insulator coated with water-repellent materials, the water falling on the surface of the insulator will not form a continuous water film and appear in the form of isolated water droplets, at this time the conductivity of the dirty layer is not large, the leakage current is very small, and the insulation is very small. It is not easy to form a gradual extension of the local arc, that is, it will not cause pollution flashover), so that the probability of pollution flashover is greatly reduced.

05 Do a good job of small animals into the preventive measures

The winter weather is cold, the warm environment of the electricity room will attract various small animals into the house, then it is easy to occur rat infestation, coupled with the nature of the transformer heat, more susceptible to rat infestation patronage. Therefore, it is necessary to check whether various holes have been sealed, to avoid short-circuit burning due to small animals entering the wrong contact.

06 The motor must be telemetered insulation before power transmission

When the production unit repairs the pump, it is required to remove the motor cable, and reconnect the motor cable after the repair of the pump. In winter, the outdoor temperature is low, the steam emission in the production unit area is more, during the cable wiring process, the moisture may enter the junction box, and there is condensation, then the insulation at the cable terminal will be reduced. In the past, such a situation occurred in chemical enterprises, the production unit operator asked to open the pump, let the electrician send electricity, the electrician pushed the switch into the working position, told that the pump can be opened, the result of the mechanical and electrical collapse accident occurred at the start of the moment, so after the maintenance of the machine pump, before the requirement of power transmission, the electrician must be telemetered insulation at the switch distribution cable in the substation, and the insulation can be qualified before power transmission.

07 Check the heating equipment in the substation

The lounge in the substation on duty is separated by only one wall from the high and low pressure room, and there is heating in the lounge. In the past, chemical enterprises have had heating water leakage and gas leakage. Once found not in time, water vapor enters the high and low pressure room, it will cause switch misoperation, resulting in power failure. Therefore, the personnel on duty should be inspected in time, and the phenomenon of water leakage and air leakage should be dealt with in time to prevent the normal operation of electrical equipment from being affected